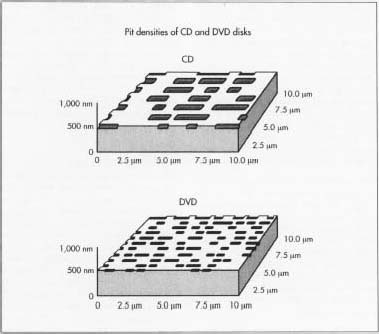

Perbandingan jumlah data compact disk dan disk DVD dapat berisi. Kepadatan pit DVD jauh lebih besar, yang memungkinkan disk untuk menyimpan setidaknya tujuh kali lebih banyak data sebagai CD.

Perbandingan jumlah data compact disk dan disk DVD dapat berisi. Kepadatan pit DVD jauh lebih besar, yang memungkinkan disk untuk menyimpan setidaknya tujuh kali lebih banyak data sebagai CD.

lapisan perak reflektif, disk dapat dibuat untuk menyimpan 2 lapis data pada satu sisi. Dengan menggunakan daya yang lebih kecil, laser dapat membaca data dari lapisan emas pertama dan kemudian dengan meningkatkan kekuatan, dapat membaca lapisan perak. Ini hampir dua kali lipat kapasitas satu sisi menjadi 8,5 GB. Akhirnya, disk dua sisi tunggal akan dapat menyimpan hingga 17 GB data.

Sejak DVD diciptakan terutama untuk film, sistem kompresi diperlukan. Untuk melakukan ini, produsen telah sepakat untuk menggunakan sistem kompresi MPEG-2 (Motion Picture Expert Group). Ini adalah sistem di mana hanya elemen gambar yang berubah dari frame ke frame disimpan. Untuk audio, Dolby digital kompresi akan digunakan. Karena kedua sistem kompresi yang digunakan, sebuah decompressor atau decoder juga harus disertakan dalam DVD player. Saat ini, ini adalah kartu yang terpisah yang dihubungkan ke komputer. Dewan decoder memproses data dari disk dan mengirimkannya tepat untuk grafis komputer dan sistem audio.

Bahan Baku

Berbagai bahan baku yang digunakan dalam pembangunan DVD player dan disk. Kaca yang digunakan untuk membuat dioda laser dan lainnya dalam sistem. Komponen utama pada papan sirkuit yang terbuat dari silikon. Logam aluminium digunakan untuk perumahan serta plastik keras. Bahan dasar disk adalah plastik. Mereka selain itu dilapisi dengan lapisan berwarna perak dan lapisan emas tipis. Permukaan disk lebih lanjut dilapisi dengan lapisan keras pernis untuk melindunginya dari kerusakan.

Manufaktur

Proses

Komponen mesin DVD biasanya diproduksi oleh perusahaan terpisah dan kemudian dirakit oleh produsen DVD. Produksi bagian komponen adalah proses yang sangat khusus, dan hanya beberapa perusahaan yang dilengkapi untuk memasok seluruh industri. Komponen utama meliputi perakitan sistem optik,

A

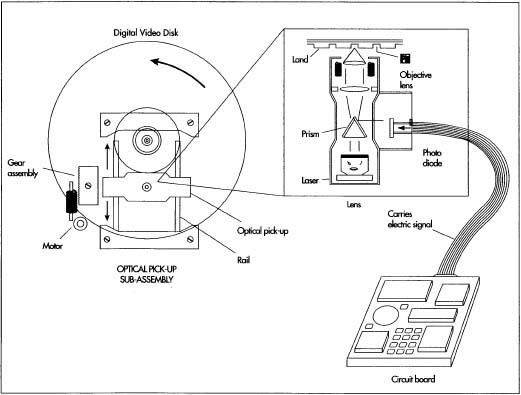

DVD player consists of advanced electronics, including the mechanism of

disk drives, printed circuit boards and assembly of optical systems. It consists of a spindle that holds the disk and a motor that rotates it. Circuit board contains all electronic components, which helps to convert the data being read into a format that can be used. Assembly of the optical system is part of the DVD that reads data from the disk and sends to be converted into binary code.A

DVD player consists of advanced electronics, including the mechanism of

disk drives, printed circuit boards and assembly of optical systems. It consists of a spindle that holds the disk and a motor that rotates it. Circuit board contains all electronic components, which helps to convert the data being read into a format that can be used. Assembly of the optical system is part of the DVD that reads data from the disk and sends to be converted into binary code.internal electronic circuit boards and disk drive mechanism.Optical systems* 1 The optical system consists of a laser, a photodetector, prisms, mirrors, and lenses. Laser and photodetector mounted in a plastic housing, and other components are placed in certain places. Great care was taken on the position of each piece because without alignment, the system will not perform properly. Electrical connections are installed and the optical system is then ready to be attached to the disk drive mechanism.Disk drive mechanisms* 2 optical system attached to a motor that will drive it. This

in turn is connected to other parts of the disk drive, including the

principle of the loading tray (if any) and the spindle motor. Other gears and belts are attached and the entire assembly is placed in the main body.Internal electronics* 3 The electronic components of machinery and advanced DVD using the latest technology in electronic processing. Circuit boards are manufactured much like that of other electronic equipment. The process begins with a board that has an electronic configuration printed on it. This

forum is then passed through a series of machines, which puts the right

chip, diodes, capacitors and other electronic pieces in the right

place. This process is done in a clean room to prevent the damage that can be caused by airborne dust. When completed, it is sent to the next step for soldering.* 4 A wave soldering machine used to affix electronic components to the board. Before the board is inserted into the machine however, was first washed to remove contaminants. The board then heated using infrared heat. The bottom of the board is passed over molten solder wave and through capillary action, the right place is filled. As the board was allowed to cool, the solder hardens holding the piece in place.Final assembly and packaging* 5 When all the components are ready they are assembled to produce the final product. Electronic board connected to the rest of the engine and the main cover attached. DVD

machine and then sent along with the packing station where they were

boxed together with accessories such as disc, manual, and power cord. They then put on pallets and shipped to distributors and end customers.Quality ControlTo

ensure the quality of the DVD machine, visual inspection and electrical

are done throughout the whole production process and the weaknesses

detected. In addition, the functional performance of each machine DVD finishes tested to ensure it works. This test is carried out under different environmental conditions such as excessive heat and humidity. They involve playing disk tests, which will result in a specific electronic signal. Since

most of the DVD manufacturers do not produce all their own part, they

are very dependent on their suppliers for good quality. Most manufacturers specify their own quality specifications, which their suppliers must meet.FutureDVD technology is relatively new. There are many areas that will be improved in the coming year. Key

developments for DVD including greater storage capacity, improved

reader capabilities, and an increasing number of movies are available in

DVD format.Currently, the most intensely studied of DVD technology increases data storage capabilities. While the technology has been developed to produce a 17GB disk, some companies have found ways to save even more. A new coding techniques are being developed that can make a three-fold increase in storage DVD. In this method, the hole created on the disk will have different levels of depth. This will allow the hole to encode for the numbers 0 to 8, not just 0 or 1. It is anticipated that the DVD device using this technology will be available during 1999. Other storage media also show particular promise. A recent technology has shown that it can store up to 30 GB of data. The system uses a red laser and a magnetic field to retrieve the data. The use of a blue laser allows for greater storage capacity.Another

area of improvement will be found in the DVD player the ability to

read two layers of information on one side of the disk. Although theoretically DVD player can read both layers two layers of information is rarely used because of the high cost. As technology improves however, these barriers must be overcome and the full potential of the DVD may be realized.Currently,

one of the most inhibiting factor in the development of the DVD is the

lack of a universal standard for storing and retrieving media. This is similar to the problems that developed in the 1980s between VHS and Beta video players. In the near future, this issue should be resolved when the major manufacturers agreed format DVD.

A

DVD player consists of advanced electronics, including the mechanism of

disk drives, printed circuit boards and assembly of optical systems. It consists of a spindle that holds the disk and a motor that rotates it. Circuit board contains all electronic components, which helps to convert the data being read into a format that can be used. Assembly of the optical system is part of the DVD that reads data from the disk and sends to be converted into binary code.A

DVD player consists of advanced electronics, including the mechanism of

disk drives, printed circuit boards and assembly of optical systems. It consists of a spindle that holds the disk and a motor that rotates it. Circuit board contains all electronic components, which helps to convert the data being read into a format that can be used. Assembly of the optical system is part of the DVD that reads data from the disk and sends to be converted into binary code.internal electronic circuit boards and disk drive mechanism.Optical systems* 1 The optical system consists of a laser, a photodetector, prisms, mirrors, and lenses. Laser and photodetector mounted in a plastic housing, and other components are placed in certain places. Great care was taken on the position of each piece because without alignment, the system will not perform properly. Electrical connections are installed and the optical system is then ready to be attached to the disk drive mechanism.Disk drive mechanisms* 2 optical system attached to a motor that will drive it. This

in turn is connected to other parts of the disk drive, including the

principle of the loading tray (if any) and the spindle motor. Other gears and belts are attached and the entire assembly is placed in the main body.Internal electronics* 3 The electronic components of machinery and advanced DVD using the latest technology in electronic processing. Circuit boards are manufactured much like that of other electronic equipment. The process begins with a board that has an electronic configuration printed on it. This

forum is then passed through a series of machines, which puts the right

chip, diodes, capacitors and other electronic pieces in the right

place. This process is done in a clean room to prevent the damage that can be caused by airborne dust. When completed, it is sent to the next step for soldering.* 4 A wave soldering machine used to affix electronic components to the board. Before the board is inserted into the machine however, was first washed to remove contaminants. The board then heated using infrared heat. The bottom of the board is passed over molten solder wave and through capillary action, the right place is filled. As the board was allowed to cool, the solder hardens holding the piece in place.Final assembly and packaging* 5 When all the components are ready they are assembled to produce the final product. Electronic board connected to the rest of the engine and the main cover attached. DVD

machine and then sent along with the packing station where they were

boxed together with accessories such as disc, manual, and power cord. They then put on pallets and shipped to distributors and end customers.Quality ControlTo

ensure the quality of the DVD machine, visual inspection and electrical

are done throughout the whole production process and the weaknesses

detected. In addition, the functional performance of each machine DVD finishes tested to ensure it works. This test is carried out under different environmental conditions such as excessive heat and humidity. They involve playing disk tests, which will result in a specific electronic signal. Since

most of the DVD manufacturers do not produce all their own part, they

are very dependent on their suppliers for good quality. Most manufacturers specify their own quality specifications, which their suppliers must meet.FutureDVD technology is relatively new. There are many areas that will be improved in the coming year. Key

developments for DVD including greater storage capacity, improved

reader capabilities, and an increasing number of movies are available in

DVD format.Currently, the most intensely studied of DVD technology increases data storage capabilities. While the technology has been developed to produce a 17GB disk, some companies have found ways to save even more. A new coding techniques are being developed that can make a three-fold increase in storage DVD. In this method, the hole created on the disk will have different levels of depth. This will allow the hole to encode for the numbers 0 to 8, not just 0 or 1. It is anticipated that the DVD device using this technology will be available during 1999. Other storage media also show particular promise. A recent technology has shown that it can store up to 30 GB of data. The system uses a red laser and a magnetic field to retrieve the data. The use of a blue laser allows for greater storage capacity.Another

area of improvement will be found in the DVD player the ability to

read two layers of information on one side of the disk. Although theoretically DVD player can read both layers two layers of information is rarely used because of the high cost. As technology improves however, these barriers must be overcome and the full potential of the DVD may be realized.Currently,

one of the most inhibiting factor in the development of the DVD is the

lack of a universal standard for storing and retrieving media. This is similar to the problems that developed in the 1980s between VHS and Beta video players. In the near future, this issue should be resolved when the major manufacturers agreed format DVD.

No comments:

Post a Comment